Precision TIG Welding for Critical Clean Environments

When contamination isn’t an option, your sanitary piping systems demand the highest level of precision and cleanliness. Dunaway Custom Welding and Fabrication delivers the specialized expertise that food, beverage, and pharmaceutical facilities across Western New York trust for their most critical sanitary applications.

Why Our Sanitary Piping Services Matter

One contaminated batch can cost your operation thousands in lost product and damaged reputation. Our certified welders specialize in precision TIG welding techniques specifically designed for stainless sanitary systems. As a union Local 13 contractor, we understand that sanitary piping isn’t just about connecting pipes—it’s about protecting your product integrity and maintaining the sterile environments your processes require.

Clean Weld Procedures That Protect Your Products

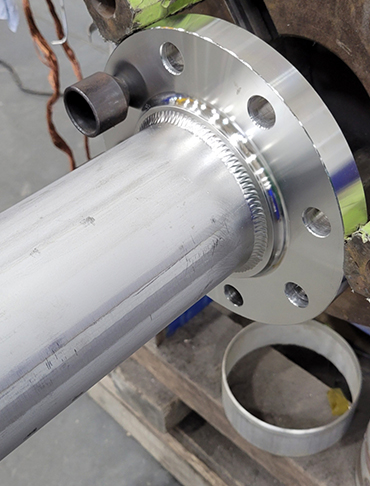

Our sanitary piping installations follow rigorous clean weld procedures from start to finish. We use specialized equipment and techniques that eliminate contamination risks while creating smooth, crevice-free joints that meet FDA and 3-A sanitary standards. Every weld is inspected for both structural integrity and sanitary compliance.

We work exclusively with high-grade stainless steel materials and maintain strict cleanliness protocols throughout installation. Our welders are trained in orbital welding techniques and manual TIG procedures that produce the consistent, high-quality results your sanitary applications demand.

Built for Food, Beverage, and Pharmaceutical Standards

Whether you’re installing new product lines, expanding existing systems, or upgrading aging sanitary piping, we bring the specialized knowledge that these industries require. We understand CIP (Clean-in-Place) system requirements, proper drainage slopes, and the importance of eliminating dead legs and other contamination risks.

Our team coordinates with your quality assurance personnel to ensure every installation meets your specific sanitary standards. We provide complete documentation and can work within your facility’s strict contamination control protocols.

Minimizing Downtime in Critical Environments

We know that sanitary system installations often require working around production schedules and maintaining sterile conditions. Our experienced team plans every project to minimize disruption while maintaining the highest safety and cleanliness standards. When emergency repairs are needed, our mobile capabilities ensure rapid response without compromising sanitary requirements.

Safety and Precision in Every Connection

At our welding and fabrication company, safety and precision are at the core of every project. From custom piping to mobile welding, we ensure every connection meets the highest industry standards. Our skilled team combines expertise, meticulous attention to detail, and strict safety protocols to deliver reliable, long-lasting results for industrial plants, manufacturers, and contractors alike.

Ready to protect your product integrity with expert sanitary piping?

Contact Dunaway Custom Welding and Fabrication today. Let’s discuss how our precision TIG welding expertise can support your critical sanitary applications.